Manufactured in Australia and tested over the last 50 years in some of the harshest Australian conditions, genuine COLORBOND® steel is far more than just ‘paint on steel’.

Source - Colorbond Steel.

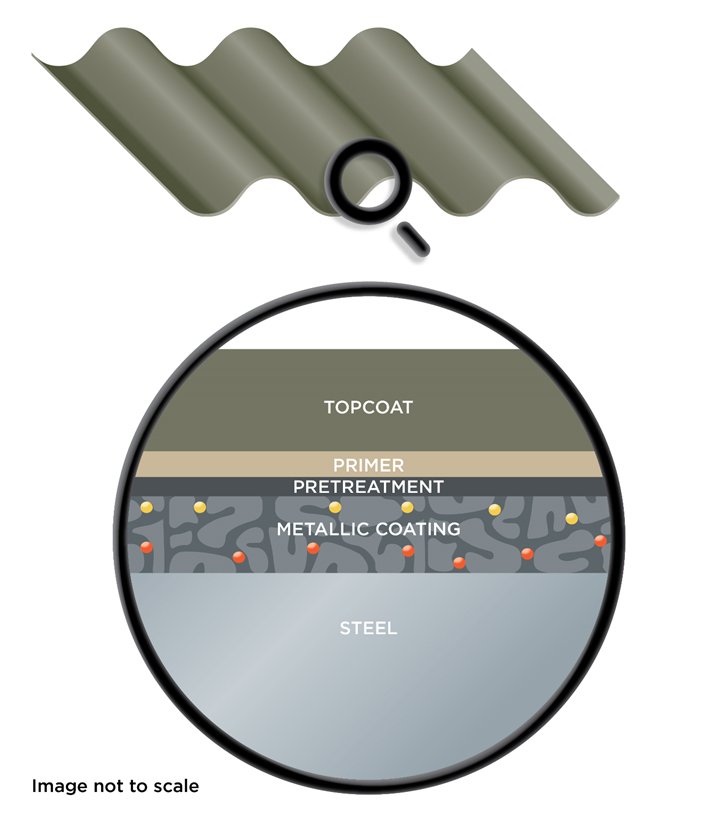

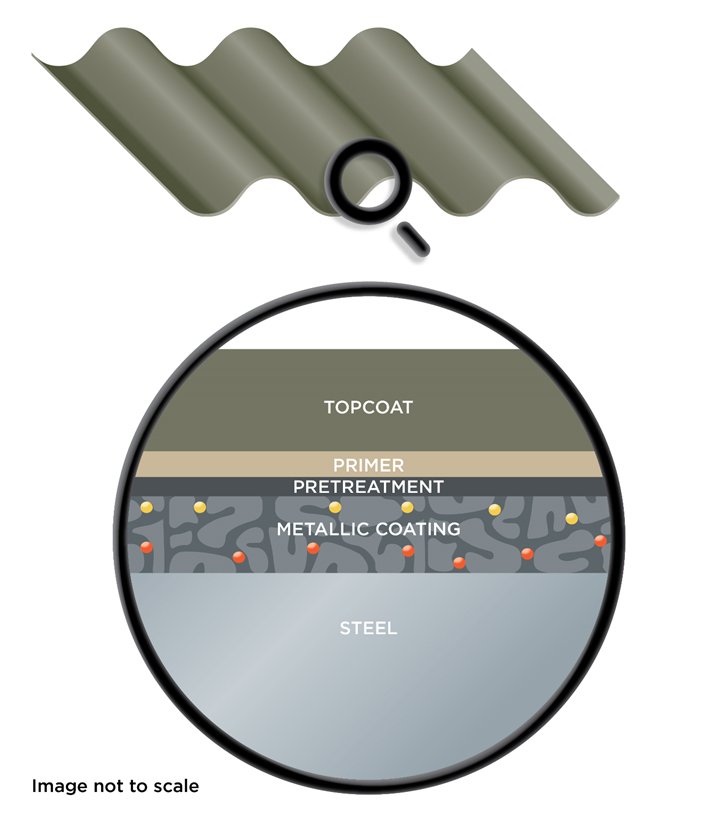

5 Layers of Protection

- The steel base is manufactured to meet relevant Australian Standards, ensuring strict adherence to the required grade and strength

- The base is then coated in BlueScope’s industry-leading metallic coating incorporating Activate® technology1, to provide enhanced corrosion resistance

- A thin pre-treatment layer is applied to optimise the adhesion of further coatings

- A corrosion inhibitive primer is baked onto the surface

- A topcoat of specially developed, exterior grade paint with Thermatech® solar reflectance technology2 is baked on to provide resistance to chipping, flaking and blistering and to ensure the finish retains its look for longer.

Activate® Technology

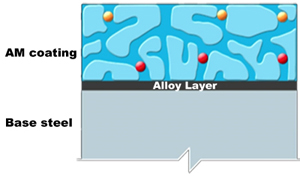

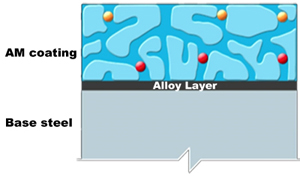

Activate® technology, is BlueScope's industry leading, patented, metallic coating technology.

The unique composition and microstructure of the aluminium / zinc / magnesium alloy coating (AM) was developed for improved corrosion resistance compared to aluminium / zinc alloy coating (AZ), and acts in three ways:

Source - Colorbond Steel.

- Magnesium, aluminium and zinc compounds are strategically positioned in the coating to provide sacrificial protection.

- Magnesium compounds encourage the formation of a more robust barrier, slowing the rate of subsequent corrosion.

- Magnesium compounds also 'activate' the metal coating resulting in more effective, longer-lasting sacrificial protection